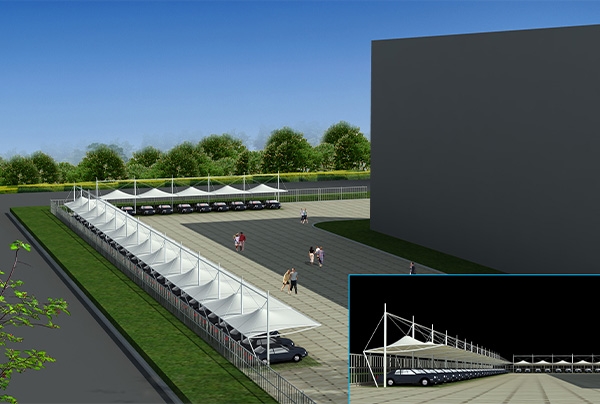

Membrane structure parking shed

Steel membrane structure shed: relying on the computer design software, according to the unique characteristics of the membrane structure, get rid of the constraints of the traditional sunlight plate steel structure, give full play to the designer's creativity in appearance, combine the local natural environment and national customs, and design a shape that conforms to the local characteristics. The membrane structure shed relies more on the curved surface to create a lively and refreshing shape, It can be harmonious with the surrounding buildings without being abrupt, which is very important for the reconstruction of bicycle sheds in some old communities. Because the newly built communities are generally designed as a whole with the community buildings, the overall feeling is stronger, and the old communities lack planning

The membrane structure design can create various shapes, which can be more appropriately integrated into the surrounding environment. The unit dead weight of the membrane material used in the membrane structure shed is only one tenth of that of traditional materials, so the shed of the same specification has lower requirements for the foundation and less steel consumption. Especially in the large-span shed project, it has natural advantages to fundamentally overcome the obstacles of traditional materials in large-span projects. Due to the lighter dead weight of the membrane structure, Therefore, its safety is also higher, which is unmatched by the traditional shed structure. As the steel membrane structure shed is processed before installation, it has low requirements for the site, and can be constructed in almost any place, so its application range is particularly wide, from schools to institutions, from communities to shopping malls, from parks to scenic spots. Generally, the service life of the membrane materials used is more than 15 years, and the characteristics of high strength, slow aging, waterproof, corrosion resistance, and UV resistance make it particularly suitable for the use of shelter facilities, while few other materials have such excellent performance at the same time, and the service life is incomparable.

The whole frame of the membrane structure parking shed adopts square steel welded keel frame. The whole frame is subject to anti rust treatment, painted with anti rust primer three times, and the surface is sprayed with white car paint. The main column of the parking shed generally uses 220mm steel pipe or I-beam steel as the support column of the parking shed. The overall structure of the shed body is firm, with high seismic and wind resistance coefficient and corrosion resistance. The whole frame of the membrane structure parking shed adopts square steel welded keel frame. The whole frame is subject to anti rust treatment, painted with anti rust primer three times, and the surface is sprayed with white car paint. The main column of the parking shed generally uses 220mm steel pipe or I-beam steel as the support column of the parking shed. The overall structure of the shed body is firm, with high seismic and wind resistance coefficient and corrosion resistance. Membrane structure parking shed Φ 38 The galvanized round pipe is welded with the shed frame to strengthen the strength of the shed top, which can make the shed feel spacious and bright, and the parking of vehicles is easy and convenient, which fully meets the requirements and specifications for the production of the parking shed; Membrane structure parking shed Φ 38 The galvanized round pipe is welded with the shed frame to strengthen the strength of the shed top, which can make the shed feel spacious and bright, and the parking of vehicles is easy and convenient, which fully meets the requirements and specifications for the production of the parking shed; The bottom of the column of the membrane structure parking shed is firmly welded with the embedded parts using 10mm thick steel plates. When installing the parking shed, the embedded parts are poured with concrete, and then connected with the upright with bolts. The wind resistance coefficient is high, which increases the overall firmness of the shed and can resist most levels of strong wind.