1. Introduction to cutting method

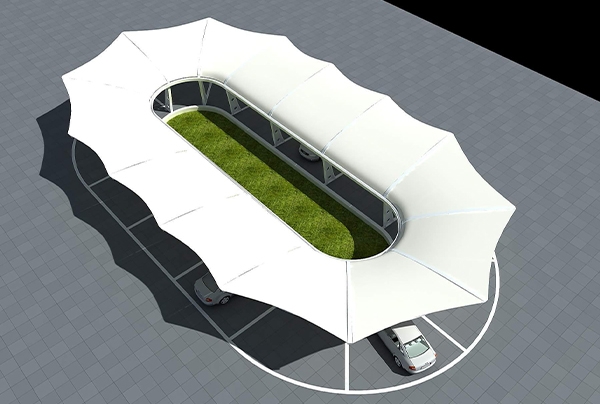

Membrane structure landscape In any case, there will be errors in the process of cutting and splicing. This is because first, there will be errors when the plane membrane is used to assemble the space surface. Second, the membrane cloth is an anisotropic nonlinear material. When it is stretched into a space shape with variable curvature, it will inevitably break even with the initial design shape. So far, many methods have been established to deal with this problem. It is difficult to evaluate which method must be accurate, but there are still several specifications that can be used to determine whether these tailoring methods are useful. That's reliability, flexibility, and deadline.

2. Interactive cutting process of membrane structure landscape

Layout of cutting seam

The following factors shall be considered when arranging the cutting joints on the surface of the membrane structure landscape shed:

1) Apparent curvature

The previous clipping methods can not give the curvature at any point of the surface. This software can get the curvature of each element because it uses curved membrane elements. If the curvature difference between adjacent elements is very large, it means that the curved surface is severely distorted in this direction. If the cutting seam is not cut off here and starts again, the gap of the cutting film block will have a large arc here. The general trend of geodesic line can be judged from the change trend of curvature of adjacent units.

2) Width of membrane material

In the process of form finding analysis, the width of the membrane material should be taken into account when dividing the plane grid. Try to ensure that the membrane unit contained in a piece of membrane cloth is intact, or the orientation of the gap point of the membrane block will be determined through interpolation calculation.

3) The trend of the gap

If the gap is relatively straight, consider using the long side of a membrane block as the gap. Otherwise, the gap can only be formed by splicing the short edges of multiple membrane blocks.

4) Beautiful

Because the membrane material is transparent and the weld can be clearly seen in the actual structure, the layout of the cutting seam must be regular and reasonable, which can form some beautiful pictures to increase the aesthetic feeling of the structure. If the membrane surface is provided with compression cord or notochord, make the cutting seam coincide with the compression cord or notochord, so that the cable will not disturb the picture layout of the weld.

The content of this article comes from the network. If you have any questions, please contact me to delete it!